JKR Large Format CNC Router Features

Designed with transport in mind

All our JKR CNC machines are designed so that they can be easily handled and moved. Moving a CNC router of this size is the most common way to damage the machine.

Box section welded to the base of machine centre of gravity to guide forklift forks

Heavy-duty M24 legs allow the machine to be leveled and also lowered onto heavy-duty castors for easy movement on flat surfaces

A forklift can push from the end side of the machine also

Extremely versatile machine to move and saves a lot of hassle and risk of damage

ISO 30 4.8kW ATC system

The machine can be supplied with a 4.8kW ISO30 automatic tool changer for full automation of all tooling and programs.

4.8kW spindle

ISO 30 holders for the tools

ER32 collet system

Holder on the machine for changing tools in collets

MTC (2.2, 3, and 6kW) and QTC (2.2 and 6kW) spindles

The machines can be supplied with manual tool change and quick tool change manual collets systems. This makes the machine more affordable and can still be a very versatile system.

2.2kW and 5kW manual tool change spindles available

2.2kW and 5kW quick tool change spindles available

If you want a special spindle let us know

All our spindles are Tekno spindles (we don’t use Chinese spindles)

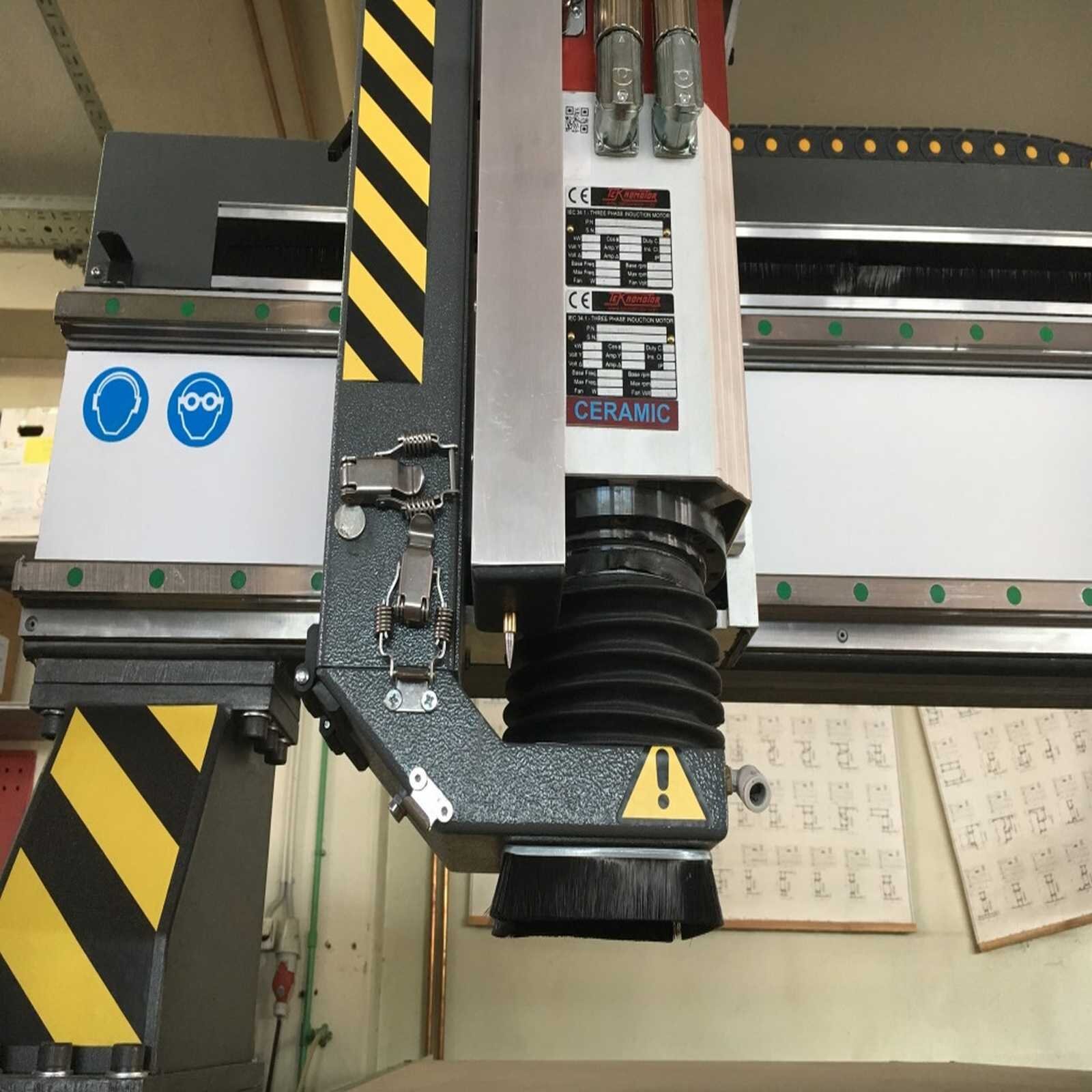

The most efficient dust shoe we have ever used

The dust shoe is fully adjustable and floats independently of the spindle. The show can be set to the height of the work.

99% efficient at dust removal

Bellow type cover between spindle and shoe

Compatible with 100mm duct extractors

Set the height of the shoe on the work and the spindle moves inside the shoeFully compatible with all auto sensors and ATC racks

It really has to be seen to be believed.

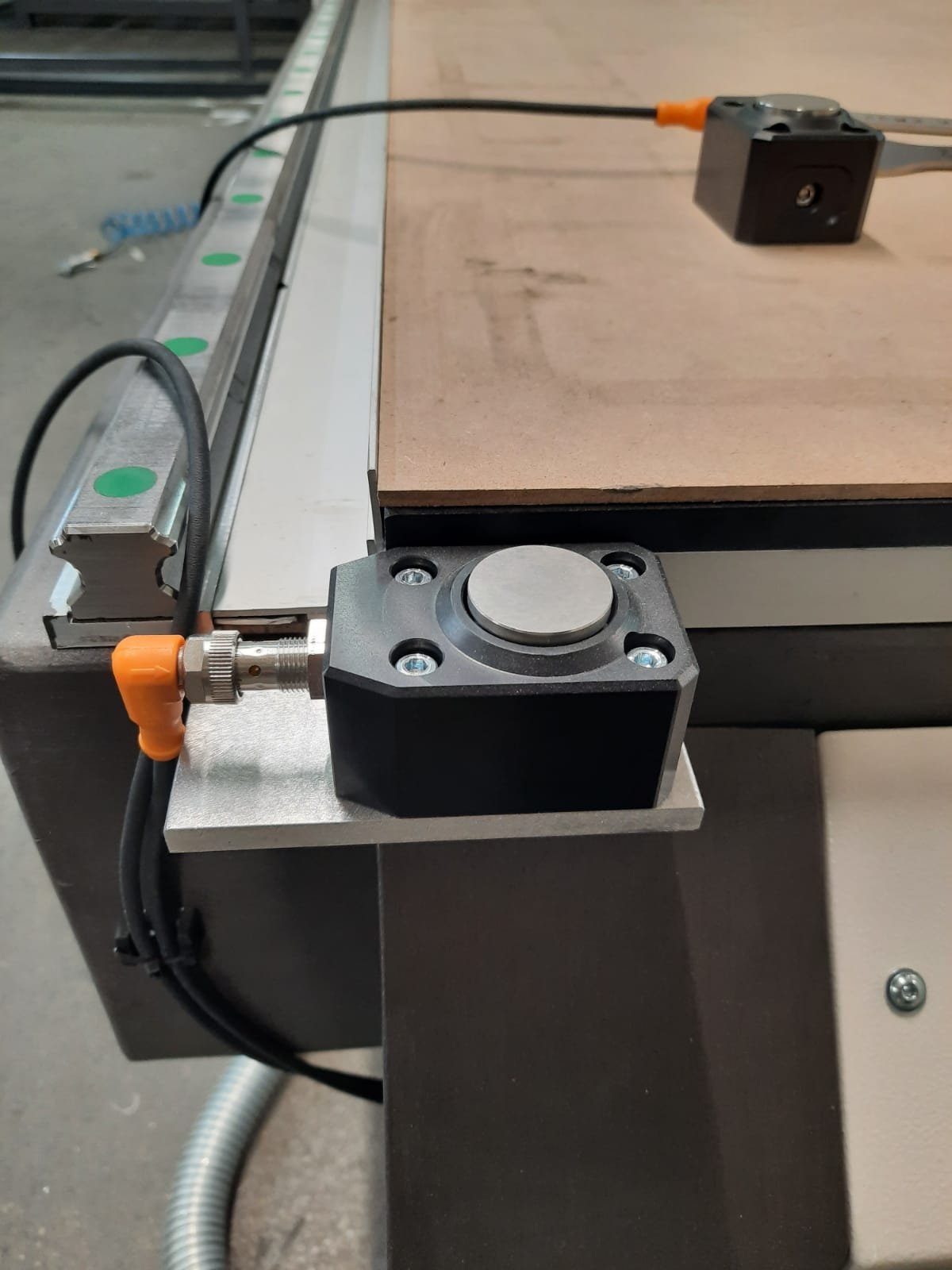

Tool management offset sensor

Every JKR CNC router machine is supplied with a tool datum setup sensor. The sensor is used as the reference plane to set up all the tools in the machine’s magazine. All tool setups are one click automated from the main controller screen.

Common datum plane for all tool set-ups

One-click tool set-up

Fast recalibration after tool breakage

Very easy to use

Optional side milling system

The JKR CNC router can be fitted with a side-loading mechanism. The bridge extends out over the side of the table and allows sheets to be loaded and milled on their edges.

This allows the edges of doors and windows to be machined

Versatile large clamping area for doors and panels

Loading plane fully datum’d to the machine for square pocketing

Utilises the full travel of the machine

Fully Phenolic vacuum table

We run dual tables split half and half across the machine. Each table has 70 zones as well as the standard grooves to place the rubber isolation strips. Each table has its own pump and the zones can be enabled and disabled easily with blanking discs. You can focus all of a pump’s pressure on a 400 x 400mm section of the table.

Dual tables as standard

Multi zones in each table with selective blanking holes

Standard grid square rubber strip isolation channels

All tables are made by the machines themselves

Fully Integrated Controller Console

All our JKR CNC machines are supplied with a full control console with an umbilical between the console and the machine. All systems are supplied with a high spec PC inside the console, backup power supply (super capacitor technology) and a touch screen.

Sheet metal control console with all controller electronics safety away from the machine

High spec industrial PC

Super-capacitor based backup power supply

Fully supported controller running on windows 10.

Upgradable to a full Laser Curtain

All controllers have integrated safety relays that allow expansion to add a full laser curtain protection system around the machine for full compliance.

1, 2 and 3 sided laser curtain installations possible

Controller fully up-gradable to laser curtain

Steel sprung floor mounted laser installation podiums

SIL Rated IFM system.

Popup - alignment pins

Pneumatically actuated pop up pins integrated into the table allowing for part alignment into the machine bed.

3 and 6 pins optional.

Pop ups actuated by rocker switches on the console

If you want a special setup let us know

Estops left and right of bridge and beside spindle as standard

All machines fitted with dual circuit redundancy E-stop systems on the left tower, right tower and beside the spindle

Approved high quality E-stop buttons

Dual circuit redundant E-stop circuits

Fully integrated into the safety relay circuit

Full Hiwin Rail and Ballscrew system on X Y an Z. Rolling Ballnuts on the Y axis

Every JKR CNC router machine is supplied running Hiwin rails and Hiwin Ballscrews. On the long axis, we rotate the ballnuts. The JKR systems have shown excellent longevity in their hardware to date.

HIWIN rails on all axes

HIWIN ballscrews on all axes

Rotating ballnut on the long axis ballscrew system

Extremely accurate and low maintenance over the life time of the machine

Contact us if you have a special application in mind

We have a host of experience in a variety of systems integration projects - if you have a challenge around automation and integration please let us know

Parallel processing cells

Handshake with robots

Custom fixture and part production setup

Contact us

Extremely focused on support

We run all machines with passively cooled Industrial PC’s running windows 10. All with dual LAN ports and WIFI connectivity. This maximises our ability to dial in and help and or diagnose an issue or a challenge facing our clients. This allows us to minimize down time and maximize your productivity

Dual LAN ports and WIFI connectivity for wired and wireless network connection in parallel to the controller

Extensive and detailed diagnosis possible of the machines operational state at any time with remote login

Intuitive interface to maximize the machines productivity

All controllers fully wired in house for our machines